- HOME PAGE

- DIAMOND & CBN GRINDING WHEELS

- CUTTING WHEELS

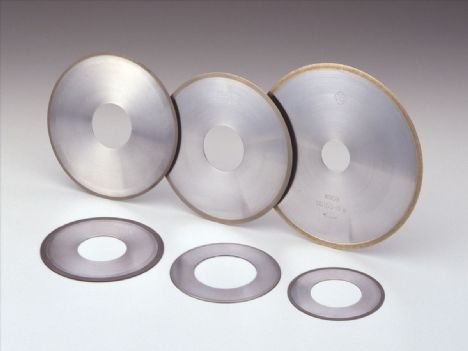

DIAMOND CUTTING WHEELS

DIAMOND CUTTING WHEELS

Product summary

These wheels are used for cutting and grooving carbide alloys, cermet, ceramics, glass, ferrites, semiconductors, carbon, and other non-iron metal materials. They realize less bending and a higher quality cutting surface. A resin bond CBN wheel is provided for cutting magnetic materials.

Component Material of the Tools・Bond

Metal bond

Electroplated

Use

DIAMOND MULTI - CUTTING WHEEL

DIAMOND MULTI - CUTTING WHEEL

Product summary

This wheel is a high-precision assembly consisting of multiple cutters (blades) that simultaneously machines complex form products of quartz, ceramics, ferrites, glass, and carbide alloys.

Component Material of the Tools・Bond

Metal bond

Use

Glass

Magnetic materials

CBN CUTTING WHEELS

CBN CUTTING WHEELS

Product summary

These high-efficiency cutting wheels are suitable for high-quality cutting of magnetic materials, ceramics, and glass. Their high cutting performance improves cutting surface quality and hence work quality.

Component Material of the Tools・Bond

Use

Glass

Magnetic materials

HI - PAX PCD CHIP SAWS

HI - PAX PCD CHIP SAWS

Product summary

These chip saws are edged with PCD (polycrystalline diamond) and can produce finer surfaces than carbide tools while lasting ten times as long. They are effective for cutting and grooving of architecture materials, wood, aluminum alloys, glass fiber composite materials, rubbers, and plastics.