- HOME PAGE

- DIAMOND & CBN GRINDING WHEELS

- DIAMOND / CBN WHEELS

DIAMOND WHELL FOR FORMING HARD BRITTLE MATERIALS

DIAMOND WHELL FOR FORMING HARD BRITTLE MATERIALS

Product summary

The "MF50" metal bond wheel is used for fine ceramics forming, glass substrate chamfering, and the forming of other hard brittle materials. Its advantages include high cutting performance and low grinding noise.

Component Material of the Tools・Bond

Use

Ceramics

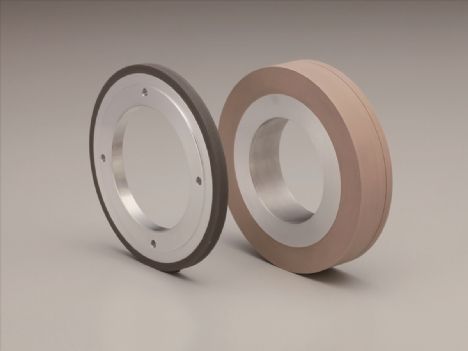

DIAMOND MOUNTED WHEELS FOR INTERIOR GRINDING OF HARD BRITTLE MATERIAL

DIAMOND MOUNTED WHEELS FOR INTERIOR GRINDING OF HARD BRITTLE MATERIAL

Product summary

There wheels are used for the internal grinding of precision parts as well as the precision grinding of glass, ceramics, carbon, ferrites, and gemstones. Wheels with bonds and specifications most appropriate to materials and usage can be provided.

Component Material of the Tools・Bond

Resin bond

Electroplated

Use

Ceramics

Magnetic materials

DIAMOND WHEEL FOR SURFACE GRNDING OF HARD BRITTLE MATERIAL

DIAMOND WHEEL FOR SURFACE GRNDING OF HARD BRITTLE MATERIAL

Product summary

This wheel is designed for surface grinding of electronic or semiconductor materials such as ceramics, quartz, and sapphires. The ""G2(G square)"" porous vitrified bond ensures high cutting performance and efficient, precision grinding can be achieved

if the wheel is combined with special segment shapes.

Component Material of the Tools・Bond

Metal bond

Resin bond

Use

Quartz

Semiconductor wafers

DIAMOND NOTCH WHEEL FOR SEMICONDUCTOR

DIAMOND NOTCH WHEEL FOR SEMICONDUCTOR

Product summary

This wheel is used for the high-precision notch grinding of semiconductor wafers. Our original processing technology realizes high swinging accuracy of the diamond part against the shank. Wheels with various specifications, such as a wheel with optimized groove shape for sapphire wafers or a wheel for mirror beveling are also available.

Details of a product

Component Material of the Tools・Bond

Use

LENELAS DIAMOND HIGH- ELASTICITIY WHEEL FOR FINISHING

LENELAS DIAMOND HIGH- ELASTICITIY WHEEL FOR FINISHING

Product summary

This wheel has high abrasion resistance because it uses a high-elasticity resin bond made with a special bonding agent. It realizes surface roughness of the same level as final lapping or polishing in a short period of time. By varying the bond content, it can be used to process different materials such as glass, metal, and ceramics. There are two types of bonds available: "RN" bond for better grinding performance and "RP" bond for better surface roughness.

Details of a product

Component Material of the Tools・Bond

Use

Ceramics

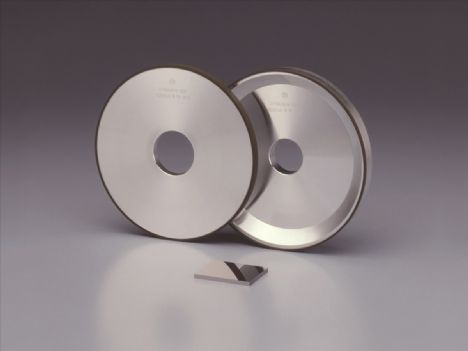

DIAMOND WHEELS FOR HEAVY GRINDING OF CARBIDE TOOLS

DIAMOND WHEELS FOR HEAVY GRINDING OF CARBIDE TOOLS

Product summary

These wheels demonstrate their distinguished performance for deep-gutter flute grinding of carbide tools. Compared to conventional resin bond wheels, they reduce machining time and abrasion. They also achieve stable cutting performance, high-precision, and high-quality surface roughness, and reduce the generation of chips. "BI30" and "MB" series resin bond wheels are also available depending on the materials to be ground and on usage.

Details of a product

Use

DEX - DIAMOND WHEEL FOR OPTICAL LENS CENTERING

DEX - DIAMOND WHEEL FOR OPTICAL LENS CENTERING

Product summary

This wheel is used for axis alignment (optical lens centering) of aspherical lenses or steppers used in high-grade cameras or endoscopes, which usually require high-precision grinding. When used, pre-conditioning grinding is not necessary and lens manufacturing with less damage on the lens edge starts from the beginning of processing work. The wheel can also suppress lens coloring, even when a steep rise shape is used.

Component Material of the Tools・Bond

Use

DIAMOND WHEEL FOR CHAMFERING GLASS SUBSTRATES

DIAMOND WHEEL FOR CHAMFERING GLASS SUBSTRATES

Product summary

This chamfering wheel is designed to maintain substrate strength when fabricating glass display panels. Wheels for facilitating high-speed substrate feeding are available for various machines.

Component Material of the Tools・Bond

Resin bond

Electroplated

Use

DIAMOND MULTI - LAYER WHEELS ( GLASS )

DIAMOND MULTI - LAYER WHEELS ( GLASS )

Product summary

A single wheel of this type can perform multiple grinding processes such as rough grinding, pre-finishing, and finishing. This allows multiple processes to be performed with a single machine without replacing tools, which reduces processing time. Multi-layer wheels with a combination of metal bonds for rough grinding, resin bonds for pre-finishing, and resin bonds for finishing are available.

Component Material of the Tools・Bond

Resin bond

Electroplated

Use

PAD DRESSER

PAD DRESSER

Product summary

This wheel is useful for dressing the polishing pads used in the planarizing process. Fixing the appropriate grinding grains of the selected diamond to a base metal realizes stable dressing and results in reduced individual differences. Dressers of various sizes, from small (φ100) to large (φ525) for DSP20B, can be supplied.

Component Material of the Tools・Bond

Use

DEX - DIAMOND WHEELS FOR CHAMFERING GLASS DISK

DEX - DIAMOND WHEELS FOR CHAMFERING GLASS DISK

Product summary

These wheels are used to chamfer the inner diameter (ID) or outer diameter (OD) edge of glass disks. Due to the special electroplating used in this design, the roughness of chamfered surfaces are improved and chipping at the boundary area to the edge surface is minimized. Wheels using micron size abrasive grain are available.

Component Material of the Tools・Bond

Use

DEX-DIAMOND WHEEL FOR HIGH EFFICIENCY MILLIG OF DIFFICULT TO CUT MATERIAL

DEX-DIAMOND WHEEL FOR HIGH EFFICIENCY MILLIG OF DIFFICULT TO CUT MATERIAL

Product summary

This wheel enables deep milling of difficult-to-cut composite fiber materials such as brake linings, architectural ceramic materials, secondary products of cement, carbon, FRP, and thermoset resins. The amount of ground material removed per unit time is relatively large, which realizes highly efficient grinding. By controlling the contact area between the material being ground and the wheel, this design reduces grinding noise, suppresses additional electric current in the main spindle, and contributes to energy saving.

Component Material of the Tools・Bond

Use

DEX- DIAMOND WHEELS FOR FORMING DIFFILT TO CUT MATERIAL

DEX- DIAMOND WHEELS FOR FORMING DIFFILT TO CUT MATERIAL

Product summary

These wheels are designed for high shape precision forming of, for example, motor cores. Wheels of the most appropriate specifications are available for not only magnetic materials such as neodymium-iron, but also for ferrites, ceramics and glass.

Component Material of the Tools・Bond

Use

Ceramics

Magnetic materials

DIAMOND WHEELS FOR MIRROR FINISHING OF DIFICULT TO CUT MATERIAL

DIAMOND WHEELS FOR MIRROR FINISHING OF DIFICULT TO CUT MATERIAL

Product summary

"BL" porous resin bond wheels are designed for mirror grinding of carbide alloy molds, ceramics, silicon wafers, and hardening steel alloys. With the effect of pores and a heat-resistant bond strengthened by special filler, these wheels produce high quality finished surfaces while maintaining their cutting performance.

Component Material of the Tools・Bond

Use

Semiconductor wafers

Carbide

HIGH - RESPONSE - DIAMOND WHEELS FOR GRINDING PCD & CBN TOOLS

HIGH - RESPONSE - DIAMOND WHEELS FOR GRINDING PCD & CBN TOOLS

Product summary

These wheels are used for grinding PCD and PCBN tools, which have higher hardness, higher strength and higher abrasion resistance than carbide tools. Two (non-porous and porous) "high-RESPONSE" bond types are available to meet customer needs for higher precision and higher efficiency.

Component Material of the Tools・Bond

Use

CBN WHEELS FOR HEAVY GRINDING OF HIGH SPEED TOOLS

CBN WHEELS FOR HEAVY GRINDING OF HIGH SPEED TOOLS

Product summary

The highly durable "BJ0" resin bond wheel is useful for flute grinding of high-speed drills and taps. It has low grinding resistance in creep feed grinding of high-speed steel, thus maintaining its high cutting performance.

Component Material of the Tools・Bond

Use

CBN WHEELS FOR GRINDING IRON MATERIAL

CBN WHEELS FOR GRINDING IRON MATERIAL

Product summary

These wheels realize high-precision grinding of iron materials used for automobile parts and the like. They provide the advantages of high performance and stable quality. CBN wheels with an axis are also available.

Component Material of the Tools・Bond

Vitrified bond

Use

DIAMOND WHEELS FOR BELELING SEMICONDUCOR WATER

DIAMOND WHEELS FOR BELELING SEMICONDUCOR WATER

Product summary

The "ME" and "MC4" metal bonds have higher cutting performance and durability than conventional bonds. By using a forming technology, they reduce the amount of polishing required after beveling work. Since this reduces the processing time and saves consumable supplies, the total processing cost is reduced. Wheels of desired groove shapes can be made owing to our advanced groove forming technology.Electroplated wheels using ultrafine abrasive grain are also available.

Details of a product

Component Material of the Tools・Bond

Metal bond MC4